Wide Multiple Drill Head Options

If you need to drill a number of holes in-line with one another, it is sometimes called a rail drill head or in-line pattern drill head. The name “rail drill head” or “railing drill” comes from the railing industry. Railings often have bottom and top sections that require drilled holes to locate and attach the spindles.

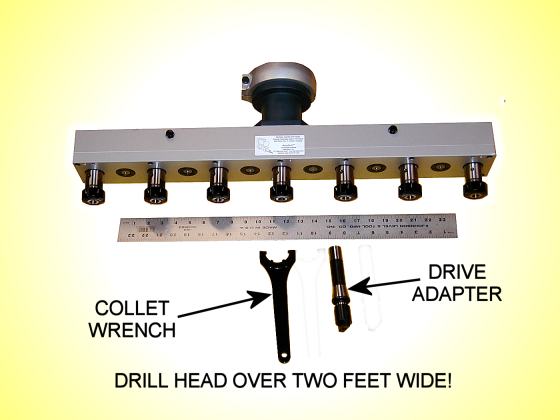

Below you can see a seven spindle head we made for a Bridgeport milling machine. Its spindles are located in-line at 3.500″ on center. We can make heads with as few spindles as you desire and at times have made heads with 36 or more chucks.

Heads such as this can be easily mounted onto a drill press to change your machine into a gang drill within minutes. The width limitation is often based on the drill press size or the horsepower available for the process. AutoDrill would be happy to examine your application, including any details of your drill press, mill, self-feeder unit, etc. and provide you with a no-obligation quote. We strive to assure you a successful project every time.

This type of multiple spindle head can be used for drilling, reaming, tapping, spinning parts or brushes, etc. and can often be customized for your actual needs. The spindles do not need to be in-line on custom heads. We are simply providing an example of that style head on this page.

To estimate the horsepower required for your process, click HERE to view a basic chart detailing the specifics for some common materials.

Please CONTACT US to discuss your application and receive prompt product cost, literature and technical help.