Hinge Drill and Production Increased

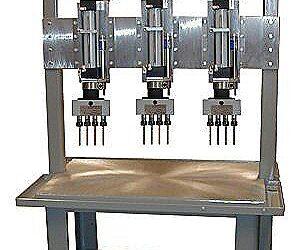

AutoDrill sold to a customer a Multi-Drill Spindle Drilling Head set-up for a customer. They were fabricating doors and larger style wood cabinets. The AutoDrill set-up increased their production capabilities by improving their efficiency. Because they needed to drill the hinge hole patterns, and we were able to help them do it more quickly, the… Continue reading Hinge Drill and Production Increased

View details